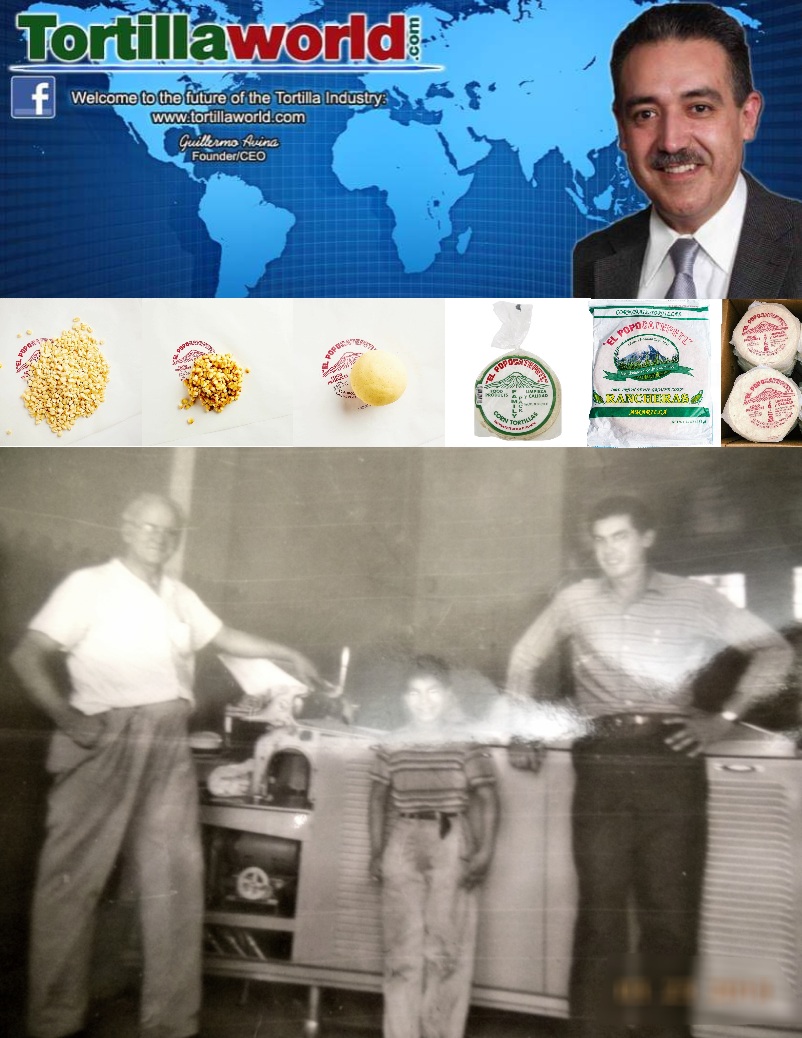

It began with my Great uncle Jose Aviña who opened a small Tortilla factory in Chicago, IL to help the growing demand for corn tortillas in 1954 in a 2 flat apartment building located in the middle of a residential area on the south side of Chicago. As the Hispanic population grew, the more tortillas he sold. In the 1960’s my father Antonio Aviña and his brother Ernesto Aviña, My uncle came from California were they worked as field workers on an orange orchid ranch to work for their uncle Jose Aviña in his small tortilla factory. They worked for him about ten years when where giving an opportunity to buy their uncles tortilla factory investing their life savings to make it happen.

In the mid 1970’s the Tortilla factory kept on growing every year. They purchased two small Tortillas factory’s in Chicago that were for sale and continued growing. I began working in the Tortilla factory’s as a thirteen year old kid on the weekends & during summer when not going to school. My first work duty was counting & stacking hot corn tortillas them neatly on the table to be hand wrapped in paper. Tortilla counter stackers did not exist yet, I remember the blisters on my fingertips caused by counting all the hot corn Tortillas by hand. I also helped load tortillas into the delivery vans by forming what I can best describe as a human line of two to three people about 3 ft. apart throwing boxes of tortillas one after another until the van could not fit any more, as soon as that van would leave, the next van was already waiting completely empty starting the same technique over & over. We did not have forklifts.

I never imagined that there would be a demand for that many tortillas back then. As I got older, I started helping out unloading truck loads of corn, 440-100 lb. burlap bags that totaled 44,000 lbs. all done by hand & using our shoulder to carry them to the small room we called a warehouse. A few years later, I started seeing the tortilla Industry equipment changing as the demand for more tortillas kept growing. I remember the first time a saw corn being cooked with steam instead of the traditional direct flame burners under the cooking tanks. It reduced our cooking time from 80 minutes to about 20 min. per tank. In the mid 1980’s we started to blend ingredients to make our own liquid preservatives to make our white corn tortillas last longer without them staling or cracking. Then we figured out we had to cool down the tortillas a lot more before putting them in plastic bags, instead of the traditional wax paper that was & still being used in Chicago today.

Adding two extra tiers to our cooling conveyors was our only option to cool down the tortillas enough before packaging them in plastic bags & sealing them with a manual hand clamp one pack at a time to make them last about twenty days without spoiling, Giving our white corn tortillas a three week shelf life allowed us to sell to Mexican restaurants & supermarkets in the surrounding states. We started selling more tortillas then we could make. We added another shift for a total of 3/8 hour shifts & on weekends. Then we purchased larger corn tortilla lines, The 30 H.P. lava stone corn grinders were replaced with new 75 H.P. lava stone corn grinders, 3 tier cooling conveyors replaced with new 7 tier cooling conveyors, New corn tortilla counter stackers that were just invented at that time. Everything that would help automate the tortilla manufacturing process at the time. That small tortilla factory that opened in 1954, now has over 250 employees. I worked there until 1996 due to family greed from all three of my brothers I decided to venture out on my own instead of watching them do what they were doing to my father.

In 2001, I started working as a sales rep for Rovey Seed Co. offering corn to tortilla and chip manufactures thru-out the US. After a few years, I noticed most of the manufactures I was offering corn to had used tortilla equipment in good running condition they were no longer using because they had purchased new or upgraded equipment. They asked me to offer it to other manufactures I was selling corn to. I started taken pictures and offering it to other customers that had mentioned they were looking for used equipment. It worked, I was selling one customers used equipment to another customer in a different city. About a year later I decided to do as a normal business instead of something I was doing on the side. I wanted to sell in a different and unique new way then all the others at the time. I started looking for a new concept to help me sell. I figured using the Internet to conveniently offer used equipment to more people faster on-line. On the 4th of July 2012, Tortillaworld.com™ went live on-line with only 3 pages total of content.

Since 2012 Tortillaworld.com™ has been building a growing reputation in the tortilla, wraps, flat-bread, chapatti & snack Industry of having the world’s largest on-line selection of new & used tortilla manufacturing equipment made in the USA offering Ingredients, lubricants & equipment replacement parts viewed monthly by thousands of tortilla Industry decision makers & professionals worldwide.